Schroeder Valves commission their new high performance flow test facility

Press release

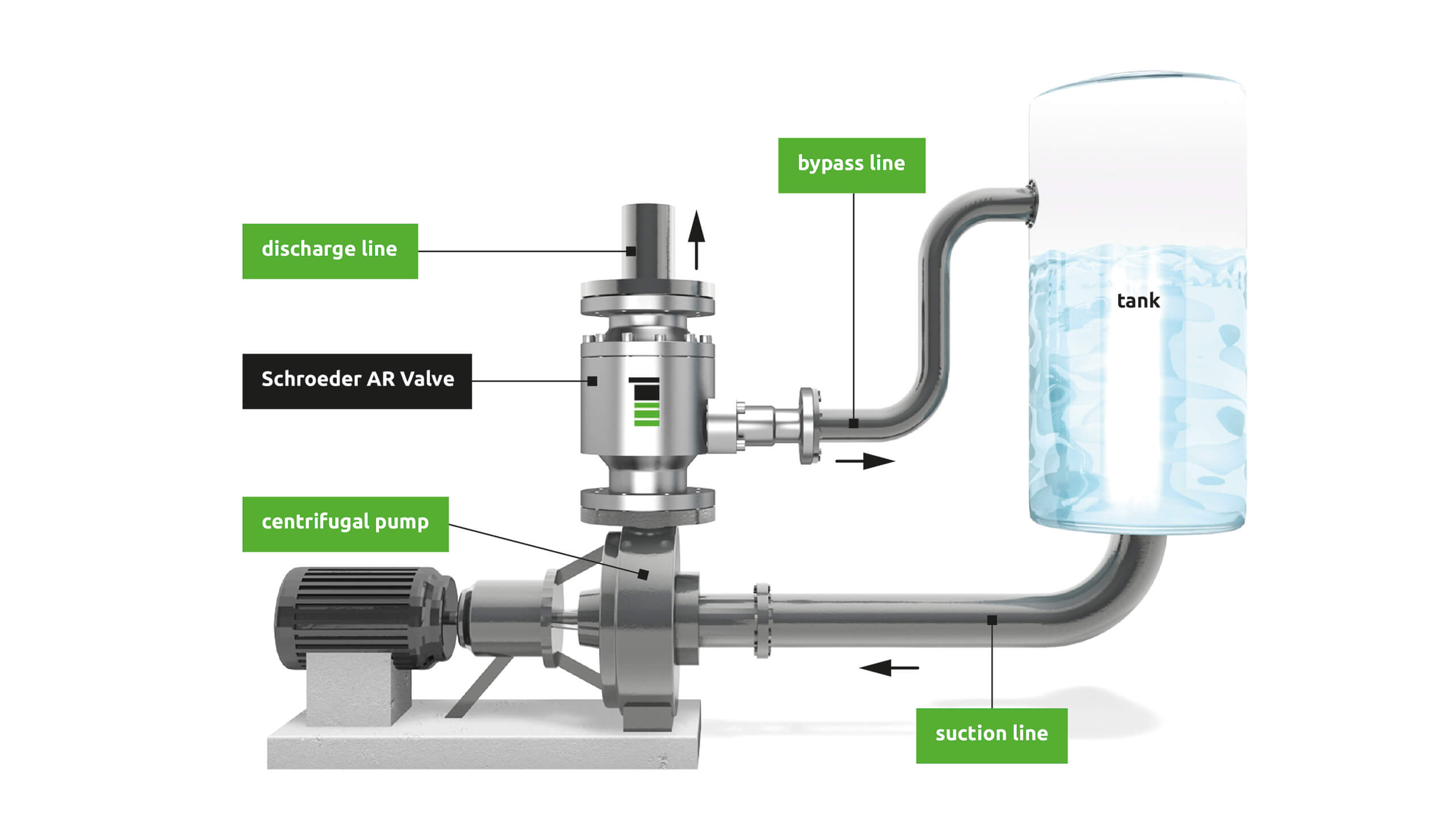

Gummersbach, February 9th 2012 Schroeder Valves' new high performance flow test loop has started operation. This facility provides increased capacity and functionality compared to the existing flow test loop that has been in operation for a number of years. The flow test facility allows Schroeder to carry out a complete functional test for each and every Automatic Recirculation Control (AR) valve prior to delivery to the customer.

The flow test loop is the centerpiece of the company’s outstanding commitment to quality control and customer satisfaction. It is one of the most advanced valve test facilities in the world with a number of impressive statistics. The water storage tank has a capacity of 80 m³ and a total of seven pumps with an individual capacity ranging from 120 m³/h up to 2,200 m³/h. The pumps are all electric motor driven with power ratings ranging from 30KW to 500 KW. Different combinations of pumps can be used together, and the maximum flow capacity of the test loop is 4000 m³/h. The flow test facility has 5 separate stations for testing valves with nominal sizes from DN 25 (1 inch) up to DN 750 (30 inch). Two independent flow tests can be carried out simultaneously.

This test facility has a state of the art PLC system that allows the flow test to be run fully automated, semi automated or manually. All of the critical performance parameters of the AR valve are measured and recorded. These include:

- Bypass flow capacity (Kv value)

- The closing point of the bypass on increasing main flow, and opening point of the bypass on decreasing main flow (Switch point)

- The pressure drop in the main flow direction measured over the full operating range of the valve.

A flow test curve is supplied as part of the quality control documentation. This test curve verifies that the valve performs to the customers' specified requirements. The flow test medium is water, and the test curve is automatically corrected for actual service liquid if the specific gravity differs from that of water. The test data is permanently stored, and can be referred to at any time following the flow test.

Schroeder Valves is a specialist for protective pump fittings. For more than 60 years, the company has been offering its customers the highest level of precision technology. Schroeder Valves-Fittings guarantee high reliability at low investments and operating costs. They are renowned around the globe for their excellent reliability and long service life.