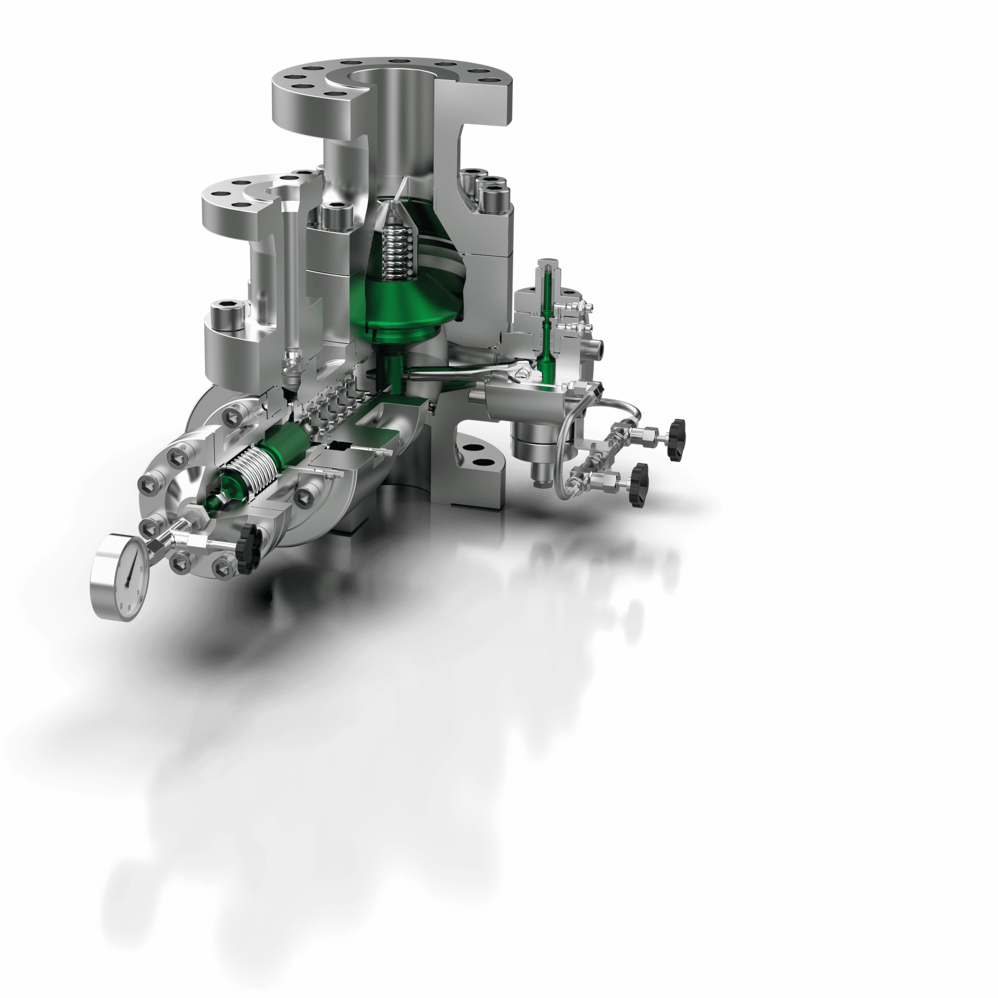

Despite its long and cumbersome name, the Automatic Recirculation Valve (AR Valve) is an inconspicuous element in the centrifugal pump circuit. The AR Valve’s main purpose is to ensure that a pre-determined minimum flow through a centrifugal pump is guaranteed at all times. This is important because centrifugal pumps operating below the minimum flow suffer from overheating, vibrations and cavitation and can be permanently damaged and even completely destroyed if they run dry.

Like a fuse in a power circuit – the AR Valve is essential for the safety of a plant.

Safety

Most centrifugal pumps operate with a constant speed along a fixed curve. The pumps are integrated into plants with variable discharge flows. The variable flows lead to operating ranges where process-related flowrates are below the required pump-specific minimum flow. These low flow conditions can cause severe incidents and downtime. The AR Valve ensures that the entire pump flowrate is greater than the required minimum flow-rate at all times. Thus, the pump is always protected from low flow conditions.

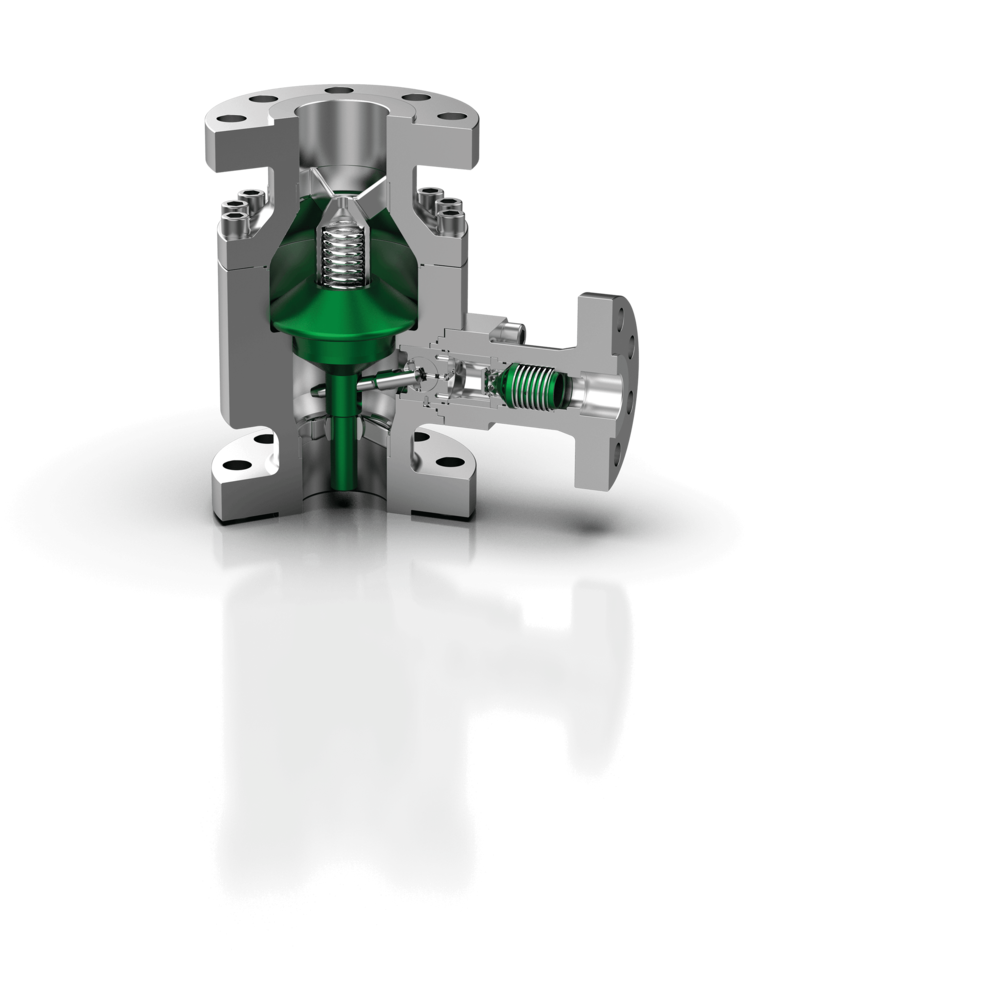

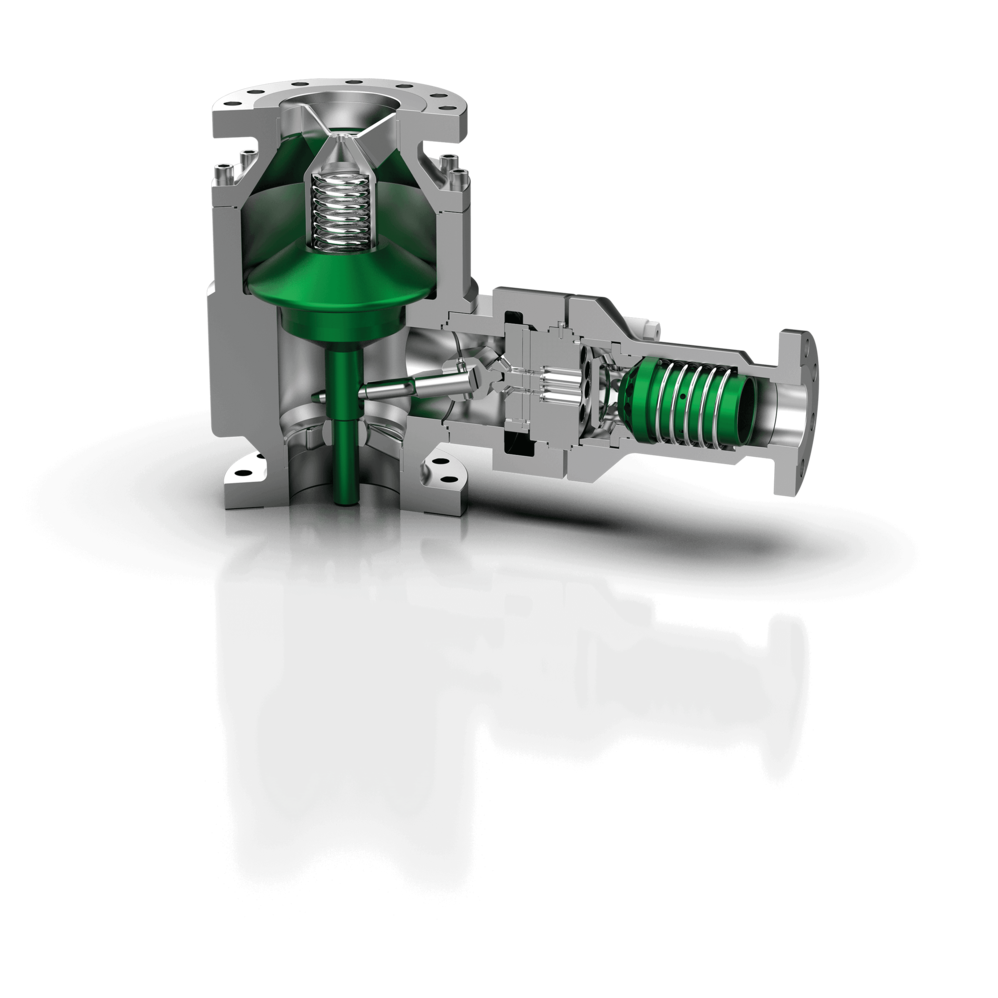

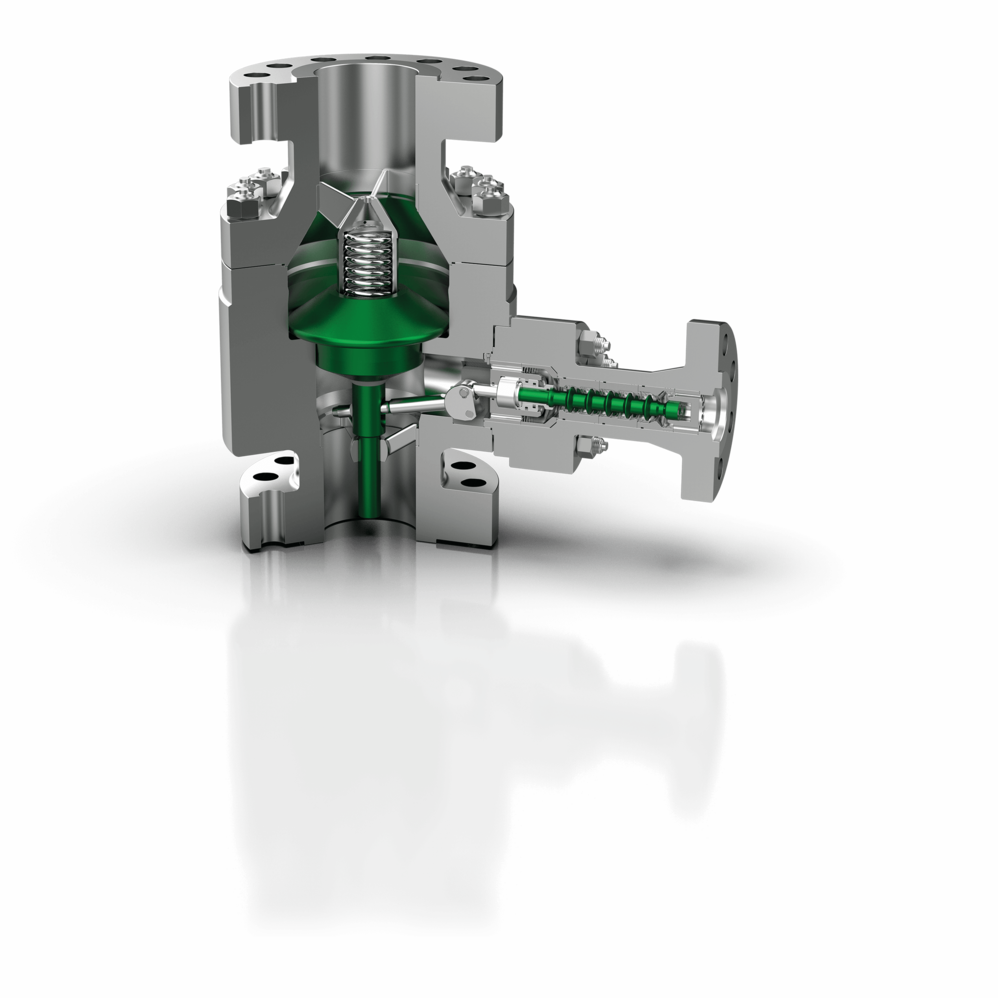

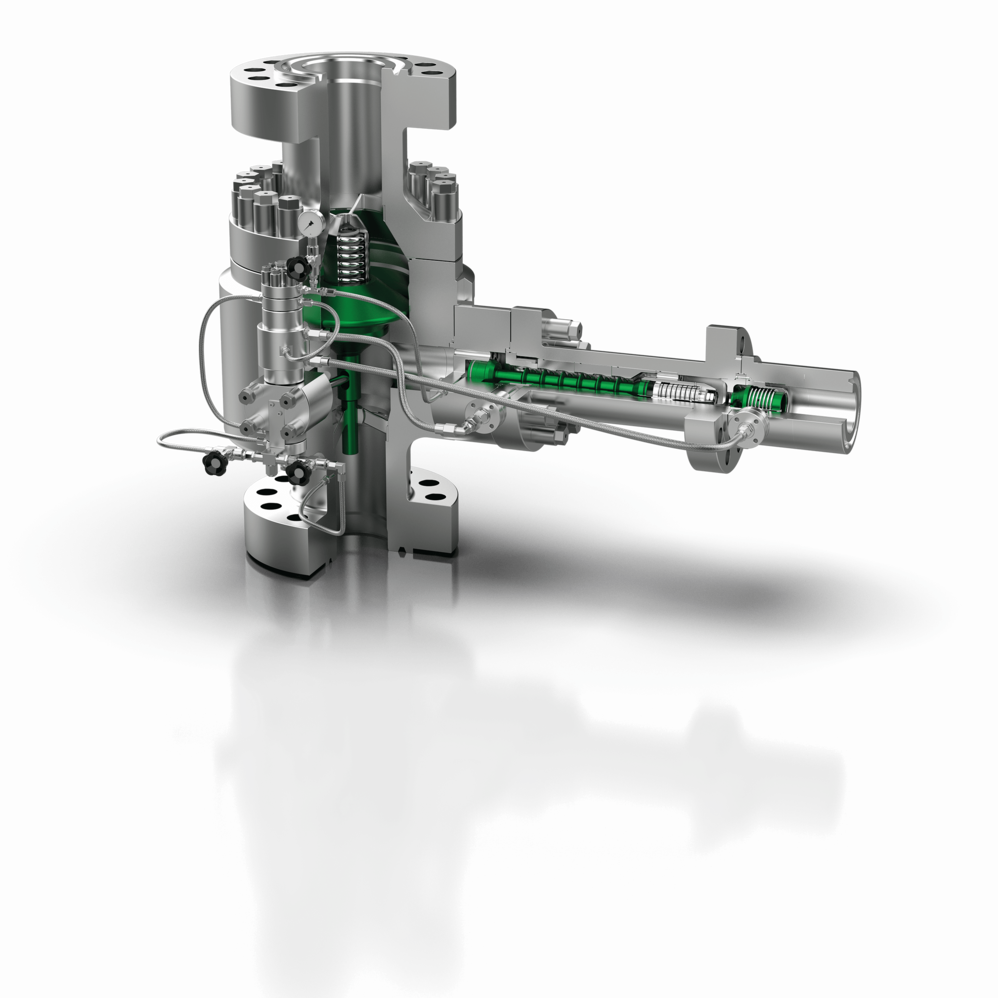

Operating principle

AR Valves are mounted on the discharge branch of the pump or in the discharge line right after the pump. The bypass branch of the valve is connected to the bypass line. The valve is solely flow-controlled. In start-up conditions with closed main line, the valve will allow the minimum flow through the bypass. As the discharge line is open, the valve will modulate flow between the process and the bypass branch. As soon as the process demand exceeds the minimum flow, the bypass will fully close and all flow through the valve is sent to process. If the actual process flowrate falls below the required minimum flow, the valve automatically opens the bypass and the determined flowrate recirculates through the bypass line to a tank or vessel.

Advantages

- combination of main line check valve and automatic bypass flow control

- perfect backflow preventer in main direction

- ideal guard against damages from overheating and cavitation

- very reliable, extremely low-maintenance and particularly durable

- reduces downtime and increases system efficiency

- no auxiliary power supply or measurement technology required

- guaranteed lower system and operating costs

- also suitable for variable rpm pumps