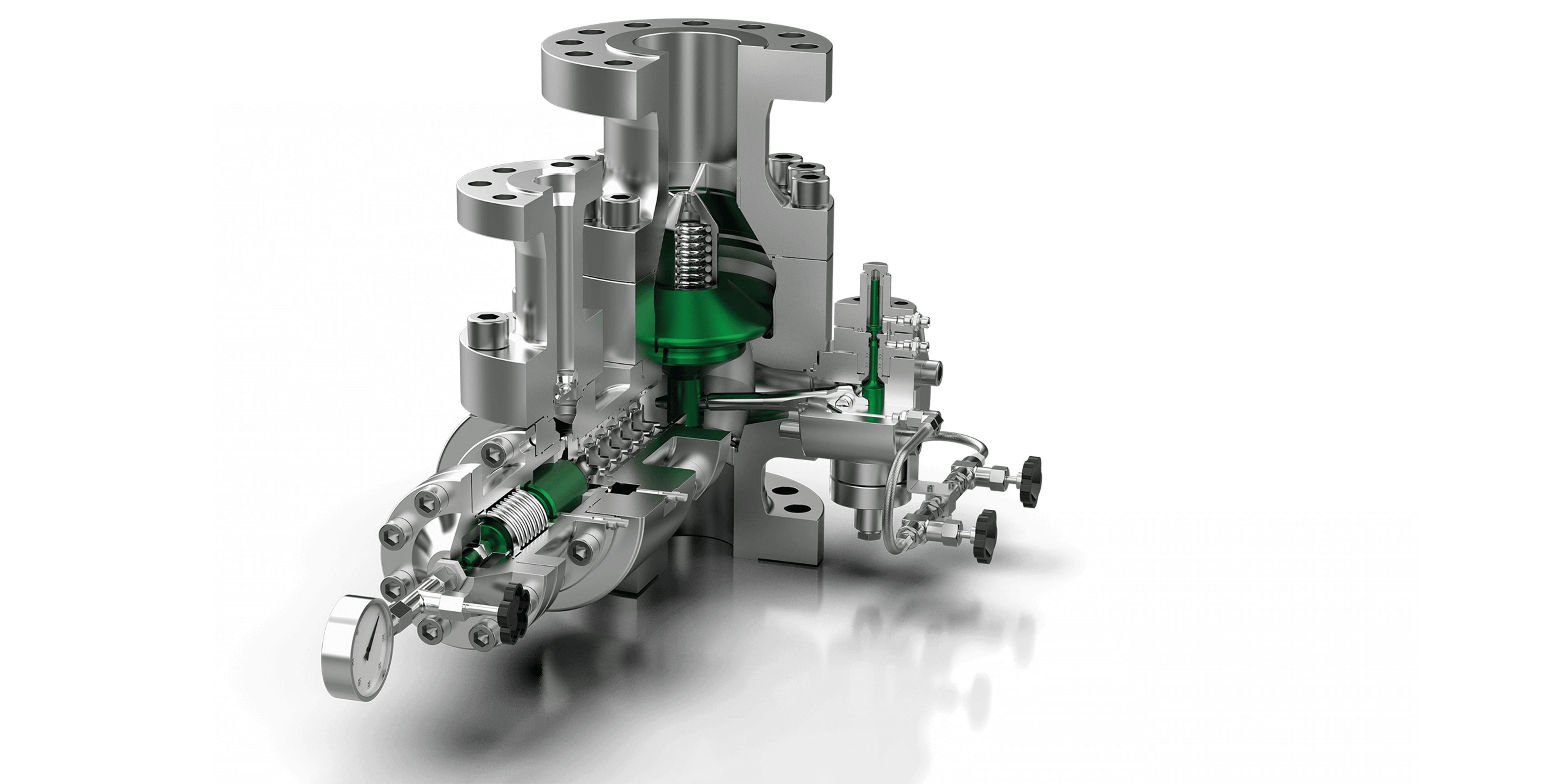

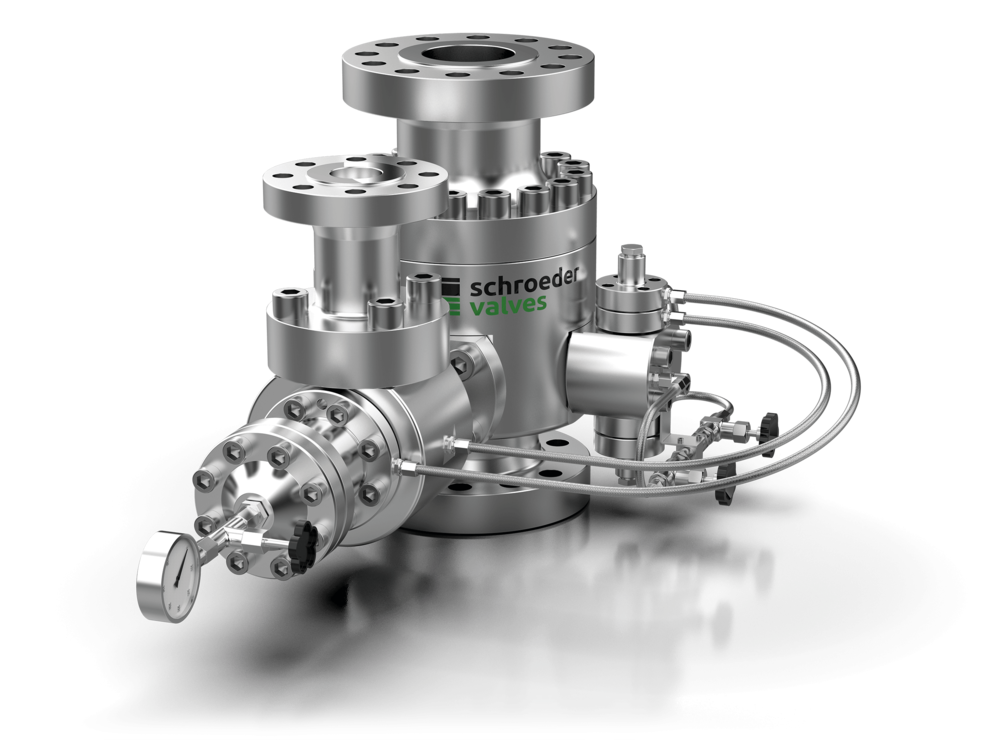

The SMA automatic minimum flow system is an AR Valve that offers low wear and very high operational safety at the highest pressure loads.

Scope

The properties of the SMA automatic minimum flow system make it the ideal valve for the protection of pumps in steel mills (descaling applications), but also for power plants or injection service in on-/offshore applications.

Operating principle

The SMA valve is equipped with an ON/OFF function: The recirculation flow is controlled by means of a piston, which is either in fully open or fully closed position. This ON/OFF-characteristic of the bypass has a switching time of max. 2 seconds. The pressure breakdown in the bypass is done by a multistage throttling system. As soon as the main pump flow falls below a predetermined value, the valve opens the bypass and safely drains the minimum volume, even if the pumping volume in the main flow direction drops to zero. The bypass is always completely opened or closed through its pilot-controlled valve piston. This ON/OFF control makes it possible to increase the previous load limit of the valves from 200 bar to > 400 bar discharge pressure. The preferred utilization range is thus between PN 250 and PN 400 or ANSI CLASS 2500. The bypass amount may be up to 35 % of the main pumping volume.

Advantages at a glance

- pressure break-down in the bypass by multistage throttles

- pilot valve operated bypass allows for low pressure loss in main line

- very low wear of pressure reducing parts