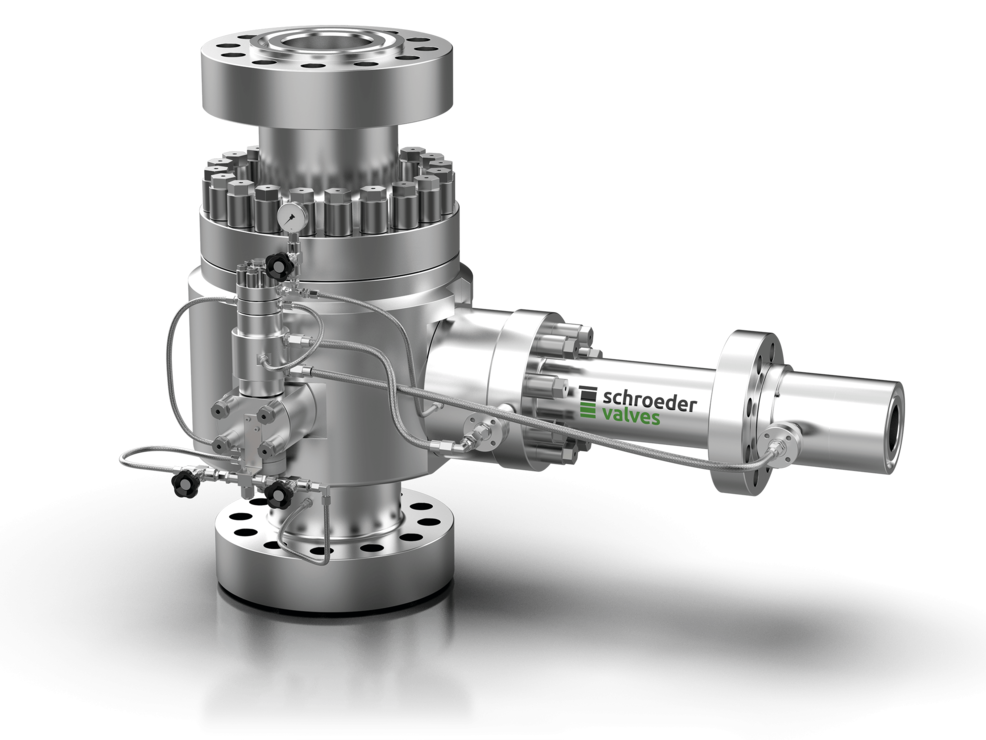

The AR Valve of our SHP series was developed for high and extremely high pressures beyond 250 bar and also works reliably under highly fluctuating load conditions.

Scope

Generally, the SHP valve applies to similar fields of services as the SIP type. Applications with frequent plant operation at minimum flow conditions with partially open bypass, i. e. split flow to process and bypass line. But due to its pilot operated powerful actuating system it is not restricted to discharge pressures below 250 bar. It can easily handle discharge pressures above 400 bar. Thus, it is also suitable for related injection services in the offshore market or high efficiency coal fired plants.

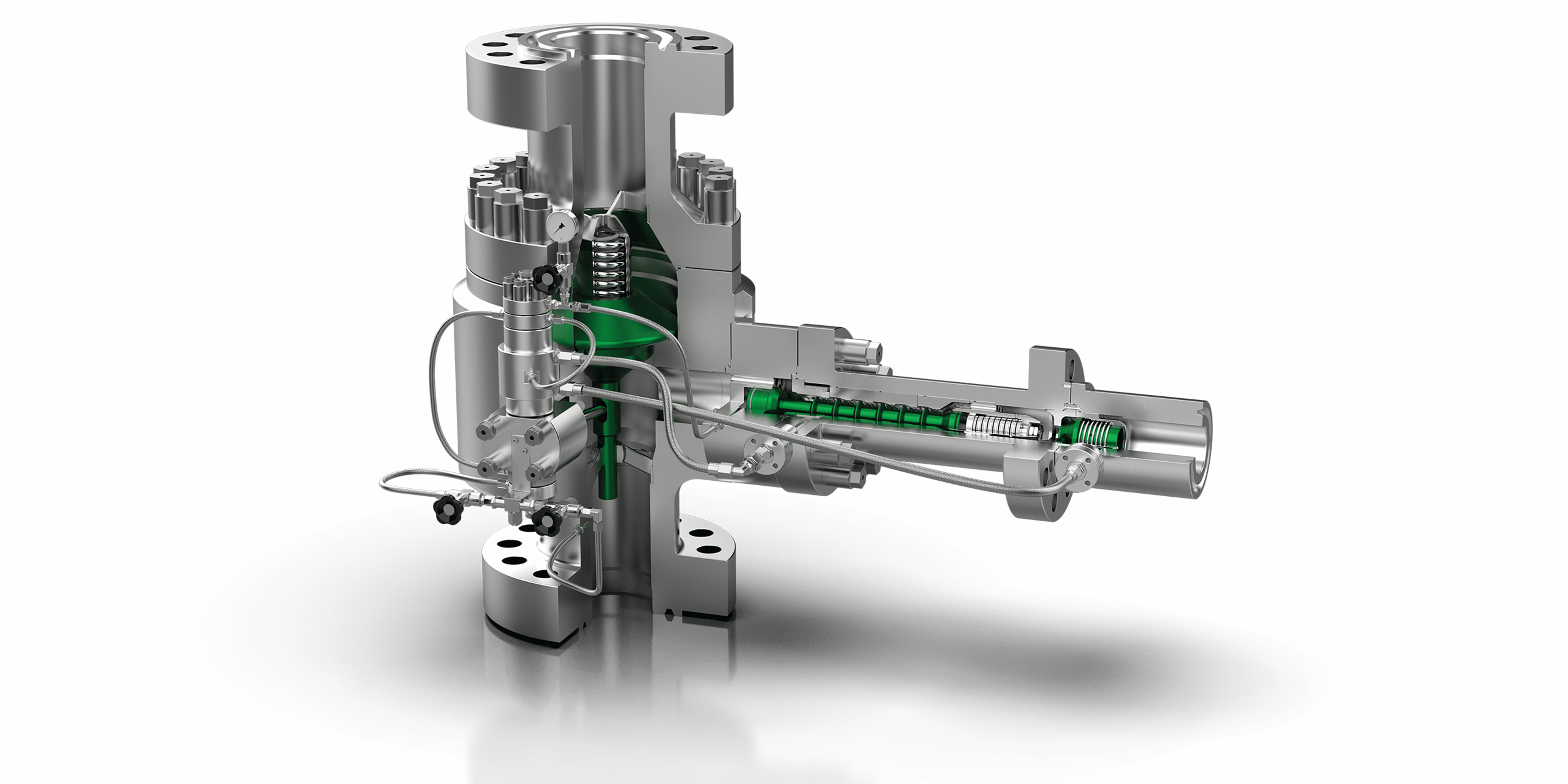

Operating principle

The bypass of the SHP valve is controlled by a multistage piston providing a near cavitation-free operation at any time thanks to the multistage pressure reduction at all flow rates. The piston also ensures a modulating flow control from 100 %–10 % bypass flow rate. An accelerated shut-off (1–2 sec.) at <10 % opening avoids most wear critical operation range. The wear-intensive extreme partial load range is deliberately overridden. The piston seat is separated from the pressure reduction and located at the high-pressure side. Thus, the shut-off function is optimally protected against cavitation attack. Even if cavitation would occur in the last throttle stages, the shut-off function would not be affected leaving the valve fully functional.

Advantages at a glance

- fully automatic minimum flow control system

- shut-off and pressure reduction are separate from each other

- SHP 18/20 with non-return valve in the bypass