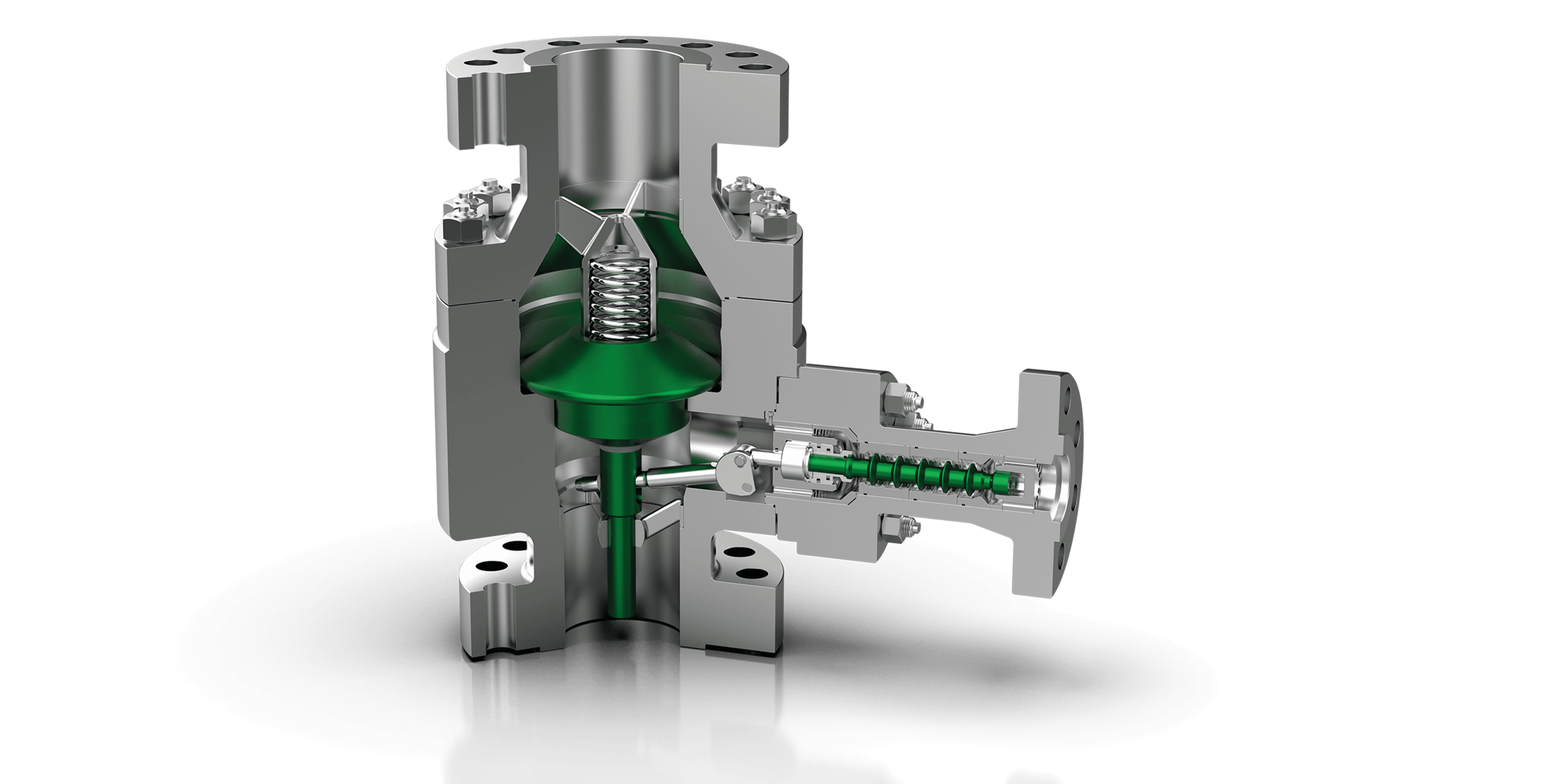

The AR Valve of our SIP series is a pump protection device particularly developed to cover applications up to

250 bar with frequent plant operation at minimum flow conditions with open bypass, i.e. split flow to process and bypass line.

Scope

The most relevant application for this valve type is the boiler feed water cycle of combined cycle power plants (CCPP). In these power plants the bfw-pumps operate frequently at minimum flow conditions with pressures of 100–250 bar. The reason is the technical concept of a CCPP – for example gas turbine cooling with bfw – as well as its purpose to cover load peaks or the natural load fluctuation of renewables in the energy grid.

Good to know: the SIP30 model is focused on the replacement of competitor valves with similar bypass technology in terms of the pressure reducing piston. That means, we have the solution to copy the main valve dimensions (S, L, H) so that a 1:1 replacement without adaptions can be achieved when replacing.

Remains to be mentioned that the SIP series has significant technological advantages that make the difference after all. Available to explain further on.

Operating principle

The bypass of the SIP valve is controlled by a multistage piston providing a near cavitation-free operation at any time thanks to the multistage pressure reduction at all flow rates. The piston also ensures a modulating flow control from 100 %–10 % bypass flow rate. An accelerated shut-off (1–2 sec.) at <10 % opening avoids most wear critical operation range. The wear-intensive extreme partial load range is deliberately overridden. The piston seat is separated from the pressure reduction and located at the high-pressure side. Thus, the shut-off function is optimally protected against cavitation attack. Even if cavitation would occur in the last throttle stages, the shut-off function would not be affected leaving the valve fully functional. Watch here the SIP Flow Animation.

Advantages at a glance

- accelerated shut-off to avoid cavitation by critical operation

- intergrated non-return function in the bypass

- no additional back-pressure regulation required

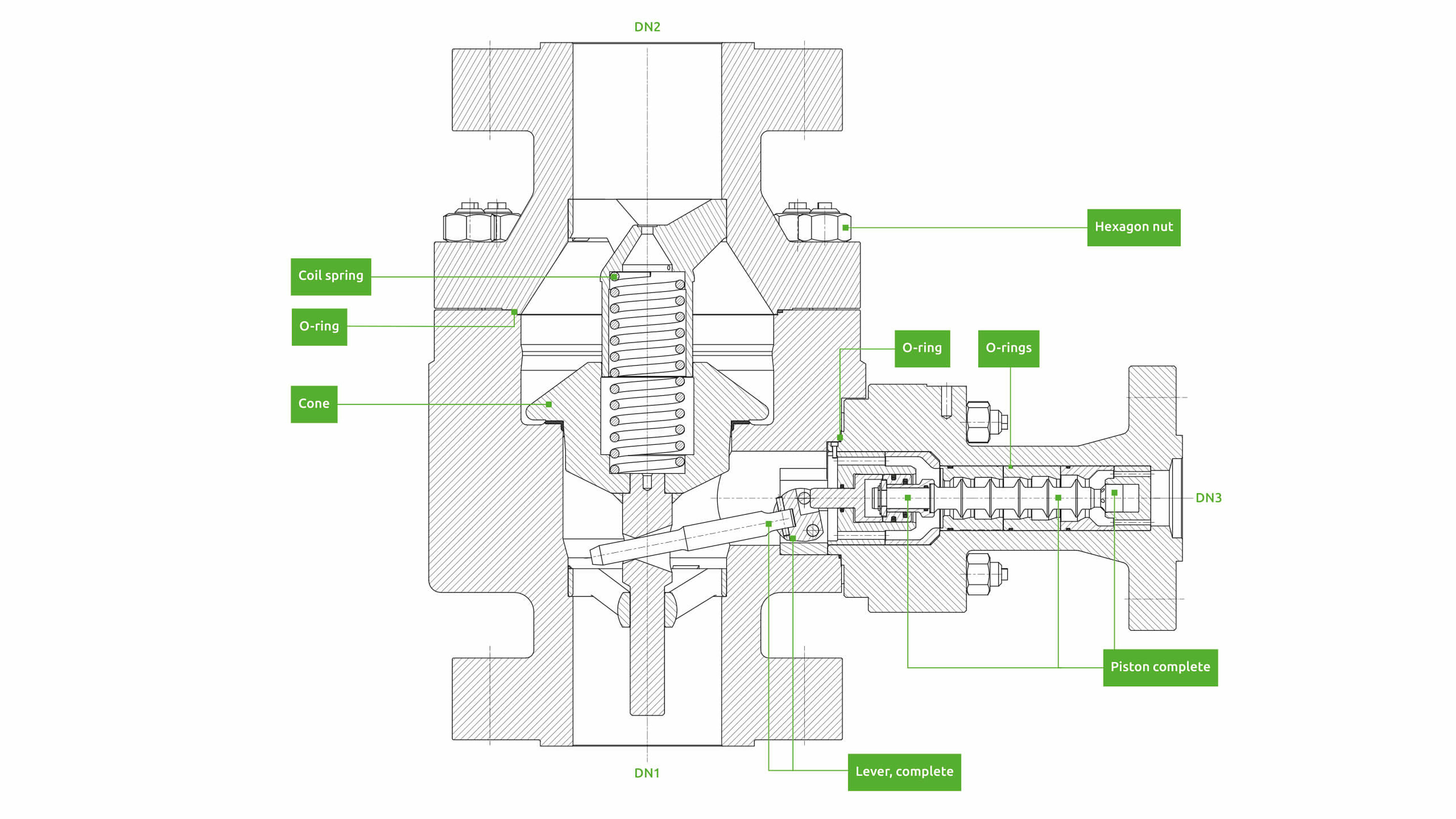

SIP Dimensional drawing:

main spare- and wear parts. Also available with DN4 branch with functions as for the SSV series.